Drymix Mortar Yearbook 2019 - Wacker

Yearbook 2019. Editor: Ferdinand Leopolder. Published on Occasion of The 7th International Drymix Mortar Conference and Industry Showcase idmmc7. Nürnberg, Germany. 18. March 2019. ISBN 978-3-9816240-8-3. Dipl.-Ing (FH) Klaus Bonin studied

consulter en ligne

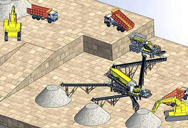

Key design technologies of the dry-mixed mortar production line

2023.11.10 Abstract: With the rapid development of China infrastructure, the dry-mixed mortar production line has a huge demand for construction enterprises. This paper

consulter en ligne

Dry Mortar Production Line: Streamlining Construction Processes

2023.7.11 A dry mortar production line is a crucial component in modern construction projects. It automates the process of mixing dry mortar, eliminating the

consulter en ligne

Quality, Efficiency, Sustainability and Available Standards of Dry

Dry mix mortars can provide better yield and thus better coverage compared to a standard site mix mortar, meaning material consumption will be less as compared to a standard

consulter en ligne

The Production Process of Dry Mix Mortar Production

The Production Process of Dry Mix Mortar Production Line (as known as dry mortar production line) is a kind of automatic dry mixed mortar mixing station controlled by advanced production equipment microcomputer

consulter en ligne

Production, delivery and storage of mortar

On-site care and mixing of factory-made mortars. The requirement for mixing on site varies according to the type of factory–produced mortar being used. Regardless of type, all dry

consulter en ligne

Characterisation and mix specification of commonly used masonry

2019.3.2 The developed detail specification can be useful to prepare the masonry mortar mix in consistent with the mortar designations specified in the design practice.

consulter en ligne

The dry ready mix mortar market- the complete guide

2020.6.30 Dry mortar refers to the dry sifted treatment of aggregate (such as quartz sand), inorganic cementite materials (such as cement), and additives (such as a polymer) according to a certain proportion of

consulter en ligne

Requirements for the Design and Configuration of Dry

Almost all the reference starting formulations of dry mix mortar have made clear requirements on the particle size range of sand, such as 0-0.3mm, 0-0.6mm, 0-1.2mm, 0-2.4mm, etc., and the gradation distribution in each

consulter en ligne

Mortar production: the most complete process - NFLG Dry Mortar

2023.6.27 The manufacturing process of mortar involves the preparation and mixing of raw materials to achieve the desired mortar properties. The specific manufacturing

consulter en ligne

>> Next:Lac Fabricants De Concasseur Erie Dans Pakistan

- poudre de pommes de terre sèche et le moulin

- fabricants rouleau d usines en inde en inde

- precio molino de malta

- ce que la taille de calcaire après broyage dans le ciment la

- mines de phosphore en amérique du sud

- fer de malaisie en particulier

- fabrication de broyage de cendres volantes en inde

- machine de traitement du verre finlande

- charbon concasseur entreprise

- apatite impact mill

- Concasseur À Mâchoires Concasseur Bci

- inde balle de la main moulin

- Occasion concasseur mobile manganèse

- installation pour le traitement de platine en europe

- mines de mica et mineraux en inde