How Cement Is Made Heidelberg Materials

4 天之前 All over the world, cement is one of the most important building materials. Whether for houses, bridges or tunnels, we cannot imagine our modern world without it. Join us for a short tour to experience how cement is made: starting with the extraction of raw materials and ending with the finished product.

consulter en ligne

How Cement is Made - Cement Manufacturing Process

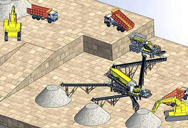

5 天之前 There are six main stages of the cement manufacturing process. Stage 1: Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite. The ore rocks are quarried and crushed into smaller pieces of about 6 inches.

consulter en ligne

(Video) How Cement Is Made - Cemex USA - CEMEX

How Cement is Made (Video) 1. Mining the raw material. Limestone and clay are blasted from rock quarries by boring the rock and setting off explosives with a negligible impact of the environment, due to the modern technology employed. 2. Transporting the raw material.

consulter en ligne

cement production Udemy

This course provides a comprehensive overview of the cement production process, from raw material selection to the final product. You'll learn about the different types of cement, the different stages of production, and the various production processes, including kiln technology, grinding and milling, and material handling.

consulter en ligne

China’s provincial process CO2 emissions from cement production

2022.4.12 24 Citations. 14 Altmetric. Metrics. Abstract. Carbon dioxide (CO 2) emissions from China’s cement production process have increased rapidly in recent decades, comprising the second-largest...

consulter en ligne

Modernizing cement manufacturing in China leads to

2022.11.17 Article. Open access. Published: 17 November 2022. Modernizing cement manufacturing in China leads to substantial environmental gains. Xiaozhen Xu, Beijia Huang, Litao Liu, Zhi Cao, Xiaofeng Gao,...

consulter en ligne

How Cement Is Made

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl

consulter en ligne

Historical trend and decarbonization pathway of China's cement

2023.9.15 For example, the projected cement production could range from 0.52 to 2.44 billion tons in 2050. We fitted the cement production by year (Fig. 7) and estimated that cement production could reach a peak of 2.28 (95 % confidential interval [CI]: 2.15–2.41 billion tons) billion tons from 2010 to 2020 and then continuously decline. By 2050, China ...

consulter en ligne

The Cement Manufacturing Process - Thermo

2023.12.20 In 2022, U.S. portland cement production increased slightly to an estimated 92 million tons, and masonry cement production increased to an estimated 2.5 million tons, according to the U.S.

consulter en ligne

Concrete Production - an overview ScienceDirect Topics

In the past decades, the demand for concrete production has been increasing along with the consumption of natural aggregates. The process requires large amounts of materials that significantly contribute to the global warming and environmental impacts. This study deals with the life-cycle assessment (LCA) of concrete production process.

consulter en ligne

فیلم فرآیند تولید سیمان در کارخانه سیمان - (۲۸ ...

4 天之前 در فرایند تولید و ساخت سیمان می بایست به منظور حذف مواد آلی موجود در آن، رس شسته شود. مواد پودر شده و آب ناشی از شستن رس که ماده چسبناکی است و به دوغاب معروف است به کانال آسیاب جهت اختلاط ...

consulter en ligne

Process technology for efficient and sustainable cement production ...

2015.12.1 Electrical energy only comprises between 10 and 15% of the overall energy demand for cement production but is a notable cost driver [4], [5].Over the last decades the average specific electrical energy consumption has decreased (Fig. 3) [6].However, there are counteracting effects: CO 2-emissions can be significantly

consulter en ligne

The Cement Manufacturing Process - Thermo

2023.12.20 In 2022, U.S. portland cement production increased slightly to an estimated 92 million tons, and masonry cement production increased to an estimated 2.5 million tons, according to the U.S.

consulter en ligne

China’s provincial process CO2 emissions from cement production

2022.4.12 In 2019, the gross cement process emissions of China amounted to 818.2 Mt CO 2, and the cumulative emissions between 1993–2019 were estimated to be approximately 12.5 Gt CO 2. There are ...

consulter en ligne

Greening cement production - Nature

2022.4.19 “Take 2019 figures for example – if green cement comprised 5% (2,912,710 tons) of the total cement production in 2019, about 820,000 tCO2 of total greenhouse gas could have been reduced.”

consulter en ligne

Decarbonising cement and concrete production: Strategies,

The heart of cement production is the kiln, where the raw materials are heated at high temperatures. The kiln operates at temperatures reaching around 1450 °C and allows for the chemical transformation of the raw materials into clinker [[37], [38], [39]].During this process, a series of complex reactions occur, including the decarbonation of limestone and the

consulter en ligne

Reducing carbon emissions in cement production through

2024.1.1 1. Introduction. The cement production industry accounts for up to 15 % of the total industrial energy consumption and produces approximately 5 % of the total anthropogenic CO 2 emissions (IEA, 2019).The basic chemistry of cement production starts with the calcination of limestone (CaCO 3) that produces calcium oxide (CaO) and

consulter en ligne

The future of Chinese cement production World Cement

2023.5.24 It is inevitable that cement consumption will decrease steadily over many years to a steady state level. Cement output dropped 10.5% to about 2.13 billion tpy in 2022. The ongoing rate of decline might be even higher. Even as the Chinese economy begins to recover in 2023, with the easing of its Covid-19 lockdowns, demand for cement is

consulter en ligne

Projecting future carbon emissions from cement production

2023.12.11 In Group 2 countries, the largest cement producer, China, started most large-scale construction of cement plants around the year 2000 and experienced rapid growth in production from around that time.

consulter en ligne

Development of lignocellulosic fiber reinforced

2021.2.22 There is a growing interest in developing cement bonded lignocellulosic fiber (LF) composites with enhanced mechanical performances. This study assessed the possibility of developing

consulter en ligne

CEMENT 101 - An introduction to the World’s most ... - Global Cement

2011.8.19 Global cement production was 1.53Bnt in 2010, excluding Chinese statistics that claim production of 1.8Bnt/yr in 2010. 14 Although China represents a major manufacturer and consumer of cement, there is well-informed skepticism surrounding its claim to produce as much cement as the rest of the world combined. 17.

consulter en ligne

Decarbonisation pathways of the cement production process

2024.1.15 Cement production, responsible for about 8 % of global carbon dioxide (CO 2) emissions [2], has widely been identified as a primary target for progressive decarbonisation efforts. In the conventional cement production process, CO 2 emissions primarily result from the production of clinker, the main component of Portland cement [3].

consulter en ligne

Cement Production - an overview ScienceDirect Topics

Production Planning Using Day-Ahead Prices in a Cement Plant. Turgay Emir, Mehmet Güray Güler, in Exergetic, Energetic and Environmental Dimensions, 2018. Abstract. Cement production is an energy-intensive process. The cost of energy constitutes more than 60% of the cost of the cement; hence cement plants have to consider minimizing the cost

consulter en ligne

Mastering Cement Production In 7 Days To Die: A Step-By

2023.9.18 Look for stone deposits, sandy areas, and clay patches to collect these materials. Craft cement mix: Open the crafting menu and select the cement mixer. Place the required amount of stone, sand, and clay into the cement mixer’s inventory. The cement mixer will automatically start the production process.

consulter en ligne

Global database of cement production assets and upstream

2023.10.13 The top five cement producing countries (China, India, Vietnam, United States and Indonesia) account for approximately 68.2% of global cement production in 2020, with China alone accounting for ...

consulter en ligne

How Cement Is Made

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore. These ingredients, when heated at high ...

consulter en ligne

Cement production global 2023 Statista

Get in touch with us now. , Apr 19, 2024. The total volume of cement production worldwide amounted to an estimated 4.1 billion tons in 2023. Back in 1995, the total global production of cement ...

consulter en ligne

Cement Production: How Cement Is Manufactured CEMEX UK

How Cement Is Made. 1. Mining the raw material. Limestone and clay are blasted from rock quarries by boring the rock and setting off explosives with a negligible impact of the environment, due to the modern technology employed. 2. Transporting the raw material.

consulter en ligne

Cement production, environmental pollution, and economic growth ...

2019.1.19 The study focuses on the nonlinear Granger causality between cement production, economic growth and carbon dioxide emissions by Markov-switching vector autoregressive (MScVAR) and Markov-switching Granger causality approach for the period of 1960–2017 for China and the USA. The empirical findings from MSIA(2)-VAR(2) for

consulter en ligne

The cement plant of tomorrow - ScienceDirect

2023.11.1 Cement plants of tomorrow will have to implement all CO 2 abatement and saving measures to the best extent possible. Reducing the clinker factor, optimising the reactivity of the clinker, substituting fossil fuels by alternative fuels and using alternative raw materials are pathways which will still play a growing role in future cement production.

consulter en ligne

(PDF) Assessment on Cement Production Practice and Potential Cement ...

2020.1.1 The construction industry is growing in a shocking rate. Ethiopia historically has low cement per capita consumption as low as 39 Kg in 2011 whereas it reached 62 kg in. 2014 which is still low ...

consulter en ligne

Video: Cement production in Sweden - The American Ceramic Society

2021.7.21 Swedish company Cementa is the sole producer of cement in Sweden, and it has plants in Slite and Skövde. The company is a subsidiary of the Germany-based HeidelbergCement Group, one of the largest building materials companies in the world. In early July, the Swedish Supreme Land and Environmental Court rejected Cementa’s

consulter en ligne

China Cement Production - TRADING ECONOMICS

Cement Production in China decreased to 15440 Ten Thousands of Tonnes in March from 15792.87 Ten Thousands of Tonnes in December of 2023. Cement Production in China averaged 9593.41 Ten Thousands of Tonnes from 1983 until 2024, reaching an all time high of 24868.68 Ten Thousands of Tonnes in May of 2020 and a record low of 781.50 Ten

consulter en ligne

Cement – Breakthrough Agenda Report 2023 – Analysis - IEA

3 天之前 Emissions intensity of cement production has risen by nearly 10% since 2015, largely due to an increase in the clinker-to-cement ratio in China. By 2030, total emissions need to fall by around 20%, enabled in part by an increase in CCUS. During the 2020s, costs of producing near-zero emission cement are likely to remain significantly higher ...

consulter en ligne

- difference de concasseur de machoire vs vs concasseur

- ciment broyeur à boulets et broyeur à boulets

- de sable et dagrégats au nigéria

- sable de pierre équipement de broyage faisant carrière de pierre

- por les broyeurs à louer amerique du sud

- Pierre Concasseur À Mâchoires Pe Pour Les Ventes En Allemagne

- la pollution causée par lusine de valorisation du minerai de fer

- basalte comme agrégat de béton

- Prix Des Broyeurs Humides A Visakhapatnam

- montant rouleau vertical mill industrie du ciment

- de coude de basalte pdf

- Séparation Magnétique Dans Le Traitement Du Kaolin

- pierre de lusine de concassage les couts dexploitation

- convoyeur à bande modulaire

- Fabricants De Ponceuse A Bande