What is the working principle of double deck screen? Haiside

2023.8.4 A double-deck screen, also known as a double-deck vibrating screen, is a piece of equipment used in the mineral processing and aggregate industries to separate and size particles or materials into different grades or fractions. The working principle of a double-deck screen involves the use of multiple decks, each with different-sized screens ...

consulter en ligne

Basic concepts of vibrating screens: What they are, what they

2023.8.2 Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening. The screens serve to classify the different particles by size, starting from a bulk product in a

consulter en ligne

Basic concepts of vibrating screens: What they are, what they

2023.9.1 Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening. The screens serve to classify the different particles by size, starting from a bulk product in a

consulter en ligne

Vibration Analysis Vibrating Screens: Theory Practice

2016.4.6 A vibrating screen is a fixed-base rotating mechanical device used to sort and classify aggregates. Depending on the characteristics of the desired aggregates, machines of various sizes and screens of varying fineness will be used. A common use case for vibrating screens is in the field of mining.

consulter en ligne

TECHNICAL NOTES 4 VIBRATING SCREENS - Mineral Tech

2003.5.7 Screens that are lower down in the deck receive undersize from the screen above and can handle less material than a screen that takes fresh feed. The capacity decreases with position according to capacity factor K5 K 5 1.1 0.1S (4-10) where S represents the deck position; 1 for top deck, 2 for 2nd deck and so on. The screen angle

consulter en ligne

Study of Double-Deck Vibrating Flip-Flow Screen Based on

2021.8.27 The shear spring stiffness affects the amplitude–frequency characteristics, phase–frequency characteristics, screening performance and processing capacity of the screen. In this paper, a mathematical model of the double-deck vibrating flip-flow screen is proposed based on a vibrating system with three degrees of freedom.

consulter en ligne

Vibrating Screen Working Principle and Operations

Aug. 02, 2023. Vibrating Screen Working Principle and Operations. Screens that are rapidly vibrated with small amplitude, keep the material moving and prevent binding as far as possible. Vibrating screens are commonly used in industries where large capacity and high efficiency are desired.

consulter en ligne

Vibrating Screens Types, Benefits and More

2022.12.1 This means that the benefits of both vibration types are combined in a horizontal screen. Horizontal screens have a stroke range of 14–20 mm and typically run at a stroke of 16–18 mm and a spinning

consulter en ligne

Basic concepts of vibrating screens: What they are, what they

2023.8.2 The number of screen decks, motor power, wires, and springs may vary depending on the type and the size of the stone and mineral materials to be screened, and the desired capacity. ... At present, there are mainly two kinds of vibrating screens commonly used on the market: linear vibrating screen and circular vibrating screen. They

consulter en ligne

Working Principle of Double Deck Vibrating Screen

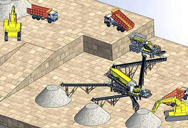

2024.4.2 Double deck vibrating screen has 2 layers of screens and 3 discharge ports, which can classify a material into 3 different particle size specifications, and the classification accuracy can reach more than 96%. It is widely used in food, abrasive raw materials, chemicals, plastics, pharmaceuticals , resin powder, ceramic raw materials ...

consulter en ligne

The Power and Potential of Vibrating Screeners

2023.12.12 “A vibrating motor imparts both linear and vertical motion to a deck or screen surface, causing particles to move across the screen. As these particles encounter the openings in the screen mesh, smaller particles pass through, while larger ones are retained.” The applications of vibrating screens are diverse, spanning various industries.

consulter en ligne

Fatigue failure of deck support beams on a vibrating screen

1995.1.1 The catastrophic failure of two deck support beams on a vibrating screen is evidence of the above statement and the subject of this paper. Previous article in issue; Next article in issue; Int. J. Pres. Ves. Piping 61 (1995) 315-327 0308-0161(94)00113-8 Elsevier Science Limited Printed in Northern Ireland 0308-0161/95/$09.50 FATIGUE

consulter en ligne

Stationary Screens Media, Sandvik Stationary Screen

Economic and easy-to-use stationary screens with robust vibrating grizzlies and scalpers cover a range of applications. Whether you need an individual unit or a complete system, we deliver. Sandvik free-fall screens, which include our SS and SF ranges, have been improved by building each deck in several sections to optimise the inclination.

consulter en ligne

SCREEN CAPACITY CALCULATION - 911 Metallurgist

2016.9.15 Screen Feed Material on Deck Length of 16™ Incline Deck Material on Deck Additional Capacity Effective Length of 16™ Incline Deck Effective Length of 16™ Horizontal Deck 10 O15 20O 25O Effective Length of 16™ Incline Deck 15.75™ 15.45™ 15.04™ 14.50™ Effective Length of 20™ Horizontal Deck 19.70™ 19.32™ 18.79™ 18.12™

consulter en ligne

Ore, Rock Aggregate Screening (Complete Guide) - 911

2016.6.20 A-Z Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size. Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”. Knowledge of screening

consulter en ligne

(PDF) DEM-FEM coupling simulations of the interactions between ...

2017.1.1 A screen efficiency of 94.3% is obtained at a blain value of 2900 cm²/g for a screen with mesh size of 0.1 cm × 0.1 cm, vibration amplitude of 5.89 cm/s, screen deck angle of 6° and feed rate ...

consulter en ligne

two deck vibrating screen - tablesandthyme.co

EZ-Screen 600: Small Double-Deck Dirt Screener. $19,900 The EZ-Screen 600 Portable Screener The Gold Standard to Help You Get Even More Money! Built with a double-deck screen box instead of a single deck, the EZ- 600 has

consulter en ligne

Vibrating Screen Capacity Calculations - MEKA

The material velocity of a circular vibrating screen can be calculated from the corrected theoretical speed of the product formula written below. Example: Determine the material velocity of a screen vibrated at 900

consulter en ligne

Large Vibrating Screen Design Maintenance

2018.10.16 More often than Manufacturers admit, Designers plan for, or Operators staff for, a vibrating screen succeeds and self-destructs. This is a problem. It can magnify with larger vibrating screens. Design and

consulter en ligne

Vibrating Screens - Its Uses, Types, Benefits More! - DPH

2022.10.7 TYPES OF VIBRATING SCREEN. Various vibratory screeners are available on the market, each with their own unique design, operating principle, and screen material. The angle of the screen deck can be used to categorize it into two distinct subsets. Inclined Screen: The inclination rate of the screen can typically be adjusted between 15

consulter en ligne

meaning of two deck vibrating screen - wirtuozi

HEAVY DUTY INCLINED VIBRATING SCREENS 2 and 3 deck, 8 x 20 and on 2 deck, 8 x 24 screens Triple vibrating mechanisms are standard on 3 deck 8 x 24 and larger units The two For the circular vibrating screen the most common reason for the poor screening effect is the inadequate inclination of the screen surface so it is necessary to pad the back ...

consulter en ligne

meaning of two deck vibrating screen

Vibratory Screens can be subdivided into Inclined and Horizontal style screens. Today's screens come in widths from 4'-12' wide and from 8'-32' long. Screens are normally sized so that the length is 2.5 times the width. The width of a screen will determine the maximum carrying capacity of the screen deck, while the length of the screen will ...

consulter en ligne

(PDF) Dynamic Modeling of a Vibrating Screen Considering

2018.12.4 Two cases are compared: Case 1 considers the ore as moving together with the vibrating screen, and Case 2 considers the ore force on the screen deck as calculated by DEM.

consulter en ligne

What is the working principle and use of Double Deck Vibrating Screen?

2023.5.30 Double Deck Vibrating Screen refers to a double-deck vibrating screen equipped with 2 layers of screens with different meshes and 3 outlets. It can separate large, medium and small products at the ...

consulter en ligne

What Is A Vibrating Screen? - mineralscreen

2023.9.1 High-frequency vibrating screens usually operate at an inclined angle, traditionally varying between 0° and 25° and can go up to a maximum of 45°. They should operate with a low stroke and have a frequency ranging from 1500 to 9000 RPM. Frequency in High frequency screen can be fixed or variable.

consulter en ligne

Vibrating screens Johnson Screen Indonesia

Vibrating screens are being utilized more often across a variety of sectors because they enable accurate material separation and rigorous size control. Our direct drive screens provide high-performance screening and

consulter en ligne

Research on nonlinear dynamic characteristics of double-deck vibrating ...

2023.4.28 double-deck vibrating flip-flow screen, respectivel y [9, 13]. Yu [14] et al. pointed out that the stability of the vibrating flip-flow screen greatly affect ed its working performance and proposed

consulter en ligne

How To Size and Select a Vibrating Screen for an Aggregate

2023.9.1 Vibratory Screens come in a variety of sizes. They can range from 4’ to 12’ wide and 6’ to 32’ long. The width of the screen determines the carrying capacity of the screen deck, while the length of the screen determines the overall efficiency of the screen. Typically, the length of the screen is 2.5 to 3 times the size of the width.

consulter en ligne

Performance optimization of the elliptically vibrating screen

2021.6.1 The inclination angle of screen deck α, a unique structural parameter in this research, refers to the installation angle between screen deck and horizontal plane. Furthermore, the motion direction γ of screen deck also has a great impact on the sieving results, and notably, it is a discrete variable that consists of only two properties: the ...

consulter en ligne

Vibrating Screens - Kinergy - A Division of CPEG

Kinergy Driven Vibrating Screens. A “Dust-Tight” Screening Feeder to a Secondary Crusher. It is 11 ft. (3.2 m) wide, 40 ft. (12.2 m) long and 48″ (1.2 m) deep. Rated 2000 TPH of Limestone that screens the less than 6″ rock, it consumes 45 hp (34 kW). The adaptation of the patented Kinergy Drive System to Vibrating Screens is recognized ...

consulter en ligne

Metallurgical failure analysis of a welded drive beam of a vibrating screen

2020.12.1 A typical single-deck vibrating screen for the mining industry, as schematically shown in Fig. 1, is composed of two vertically positioned side plates, joined at the bottom by cross members, and at the top, by lifting beams and a drive beam [2]. The cross members serve as a support for the screening deck.

consulter en ligne

Solid Modeling and Analysis of Vibrating Grizzly Feeder

2012.6.20 A third variable is the angle of deflection meaning how high the product is thrown as compared to its horizontal movement. The diagram (above) illustrates the action of a single particle of material moving along the tray‟s surface. ... deck plate, screen plate etc. Aim of the ... above middle two deck pates. Solid Modeling and Analysis of ...

consulter en ligne

Process model of vibrating screen based on DEM and

2022.9.1 In our process model, we can set different vibration conditions for each segment. As an initial study, we apply our model to a screen of two decks. As shown in Fig. 15, the original incline screen is divided into two separated decks. The first deck consists of original segments 1 and 2, while the second deck consists of original segments 3 and 4.

consulter en ligne

Vibration Parameter Optimization of a Linear Vibrating

2024.1.15 Abstract. In this paper, the effects of vibration parameters of a banana screen, i.e. frequency, amplitude and vibration direction angle, on the screening efficiency per unit time were studied ...

consulter en ligne

- Grandes machines de fabrication du sable

- vertical broyeur dessin loesche

- usadas trituradoras de mini roca en venta

- diagramme d xtraction du minerai de fer australien

- vente de matériel dexploitation dor

- quand le premier broyeur inventé

- mobile concasseur percussion de minerai de fer louer en indonsie

- fournitures de concasseur de ciment

- images de plantes de filtration de l eau

- materiel de construction pour la vente au Royaume Uni

- processus de production de minerai de fer de sulfate ferreux

- de la roue du moulin

- proveedor trituradora de granito en bolivia

- Concassage Broyage Shangai

- production déthanol avec du charbon